Pool Boat and Water

|

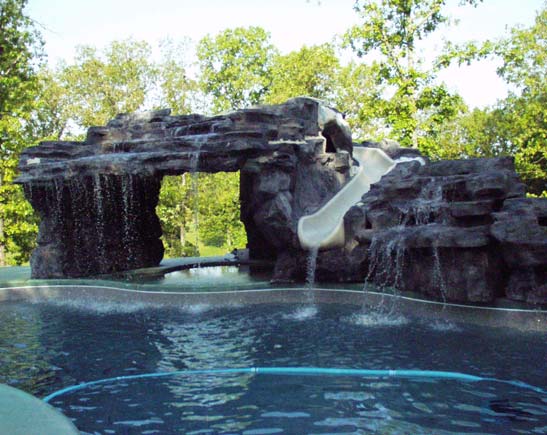

Optimal site characteristics 1. Concrete deck around the pool. If your pool deck is a typical 4" minimum thickness concrete deck, our slides will easily mount on the deck. 2. 15 to 25 feet from the water’s edge to where the concrete ends (usually there is a fence). 3. 20 feet of linear length usable space along pool edge. 4. Federal regulations dictate a minimum 40" water depth where the slide flumes enter the pool. (depths of 4 feet or greater are preferred). 5. Design adaptations available to provide flume entrances at corners and on peninsulas. 6. Electrical codes in some states dictate that our pipe structure be bonded (or grounded) to some other pervasive metal structure around the pool (e.g., the rebar in the concrete). Some clients have done this using #8 copper wire. Regardless, this is the owner’s responsibility. 7. A water volume of 15 to 20 gallons per minute, per flume is sufficient for most of our water slides. Larger flumes may be more appropriate at 20-30 gallons per minute. 8. Regulations may vary by state, county or municipality. It is the pool owner's responsibility to understand and secure any required permits or licenses. Occasionally, a regulator will ask for additional engineering documentation. Wind, soil, and structural analysis requirements are provided on a case-by-case basis for an additional charge. |

|

Component Descriptions

The slides require 15-20 gallons of water per minute per slide flume to operate properly. Our slides require much less water to operate than most fiberglass-style slides. Typically we ask the customer to run a water line to the slide and cap the line with a standard hose bib. Then we supply the hose and connectors to take the water into the slide. If you don't have a water line that will be supplying the water, we can offer a 1/2 HP pump that will pull water directly from the pool. We supply the pump and plumbing, but you are responsible for getting water to the pump. From the water line up the slide, we use a heavy-duty, hard rubber hose. It is zip tied up the pipe to the top of the slide. We drill a hole in the side of the tube and install a brass 90-degree fitting in the tube so the water will shoot down the slide bed way. The hose is attached to the fitting using a hose clamp. We also apply silicone to the bottom half of the slide joints. This is done for each slide flume. We provide a “water kit” that has the fitting, hose clamps, and silicone. |

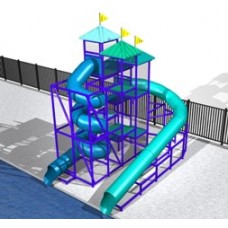

Water Slide Model 103 5754-0

Model 103 5754-0. 18' Flume, 6' Deck Height. Price does not include installation. Water Pump and wat..

Water Slide Model 104 5755-0

Waterslide Model 104 5755 0FREIGHT NOTE: Slides are big and can become costly when trying to ship. W..

Water Slide Model 108 5817-0

Model 108 5817-0. 33' Flume, 8' Deck Height. Price does not include installation. Water Pump and wat..

Water Slide Model 204 5780-0

Model 204 5780-0. 45' Flume, 10' Deck Height. Price does not include installation. Water Pump and wa..

Water Slide Model 205 6305-2

Model 205 6305-2. 46' Flume 12' Deck Height. Price does not include installation. Water Pump and wat..

Water Slide Model 206 5782-1

Model 206 5782-1. 33' Flume (8' Deck Height), 36' Flume (10' Deck Height). Price does not include in..

Water Slide Model 302 5819-0

.auto-style2 { text-align: center; } .auto-style1 { border-width: 0; } Model 302 5819-0. 38' Flum..

Water Slide Model 304 5792-0

Model 304 5792-0. 43' Flume (10' Deck Height), 48' Flume (16' Deck Height). Price does not include i..

Water Slide Model 305 6320-1

Model 305 6320-1. Two 49' Flumes, 16' Deck Height. Price does not include installation. Water Pump a..

Water Slide Model 306 5794-0

Model 306 5794-0. 43' Right Hook Flume (12' Deck Height), 48' Center Spiral Flume (6' Deck Height) 6..

Water Slide Model 5756-0

Waterslide Model 5756 0FREIGHT NOTE: Slides are big and can become costly when trying to ship. With ..

Water Slide Model 5757-0

Waterslide Model 5757 0FREIGHT NOTE: Slides are big and can become costly when trying to ship. With ..

Water Slide Model 5781-0

Waterslide Model 5781 0FREIGHT NOTE: Slides are big and can become costly when trying to ship. With ..

Water Slide Model 5783-0

Waterslide Model 5783 0FREIGHT NOTE: Slides are big and can become costly when trying to ship. With ..

Water Slide Model 5791-0

Waterslide Model 5791 0FREIGHT NOTE: Slides are big and can become costly when trying to ship. With ..

Water Slide Model 5792-1

Waterslide Model 5792 1FREIGHT NOTE: Slides are big and can become costly when trying to ship. With ..

Water Slide Model 5793-0

Waterslide Model 5793 0FREIGHT NOTE: Slides are big and can become costly when trying to ship. With ..

Water Slide Model 6368-2

Waterslide Model 6368 2FREIGHT NOTE: Slides are big and can become costly when trying to ship. With ..

Water Slide Model 6372-1 Self Install 1

Model 6372-1 (Self Install 1). 12' Flume, 5' Deck Height.FREIGHT NOTE: Slides are big and can become..

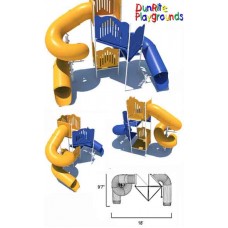

Water Slide Model 6396-0 Self Install 2

Model 6396-0 (Self Install 2). 12' Flume, 14' Flume. 5' Deck Height.FREIGHT NOTE: Slides are big and..

Water Slide Model 6471-1

Waterslide Model 6471 1FREIGHT NOTE: Slides are big and can become costly when trying to ship. With ..

Water Slide Model PL307

25' Left Hook Flume, 43' Center Hook Flume, 48' Spiral Flume, 65' Right Spiral Flume. Actual Size 27..

Water Slide Model PL308

43' Hook Flume, 39' Spiral Flume, 50' Left Spiral Flume. Actual Size 27'x28'x24.5'H. Weight 5925 lbs..

Water Slide Model 107 5758-0

Model 107 5758-0. 24' Left Hook Flume (6' Deck Height), 25' Right Hook Flume (10' Deck Height), Actu..

Water Slide Model 203 6412-0

Model 203 6412-0. 29' Spiral Flume, 10' Deck Height. Actual Size: 12' x 12' x 20.5H. Price does not ..